You obviously rebuild quite a bit and work on the engine more than the average driver. so there will not be any oil buildup since it would be cleaned and maintained. Hook up 10k# behind it and run 100k+ miles... then check your intake for oil...

RPM does not come into account of calculated maximum flow of a tube. RPM would actually provide a reduced flow due to duty factor of the pumping. you would have to account for the acceleration and deceleration of the pistons, then calculate the active pumping vs stagnant pressure time.

It is not always ring gaps that can cause blowby... ****ty rings, which you probably do not have with a specifically built engine, or out of tolerance rings can cause this.

the big points here are:

1: 99% of the truck owners are not out for a big **** contest racing people on the roads, they just want a clean well running engine.

2: I doubt the guys on here talking about a catch can are running prochargers.

3: Differential pressures are MASSIVELY different in a non NA engine and need to be accounted for. Yes, you may have got the wrong setup for your build, but a stock bolt in accessory will work on a stock configuration.

4: we are not talking about chebbys here.

(I know engines are engines

)

If you are worried about an underperforming catch can, go buy the one off the hellcat... done

The intake has been off once and that was to check a vacuum port connection, 99% of truck owners don't give a crap about a catch can and will never run on. What you have here is a forum where enthusiast congregate. The consensus HERE may be they just want a clean running truck but this forum likely represents less than 1% of buyers so, wrong.

If the rings were bad, your words, where the smoke? In my build and likely in the 5.7 HEMI as most modern engines, any "blow-by" is from the ring gaps and not bad rings.

RPM very much does play a role because the increased piston speed (frequency of strokes per min) will increase the volume of air in the crank case. IE an engine idling will have less air in the crank case thus a smaller hose/PCV system could keep up. Add more rpm and sustained RPM and that same system cant keep up so yeah, RPM factors in.

As for

"Hook up 10k# behind it and run 100k+ miles... then check your intake for oil..."

My stock 2003 Ram has 277K on it, it broke a valve spring last winter and miss-fired and blew the intake apart. When I pulled the intake, NO CATCH CAN ever, it was full of oil and not from bad rings. Additionally, you think there's less load on an engine turning 5-7500 RPM for 30-45sec multiple times a day, multiple times a week, multiple times a month for years on end than a 10k loaded 100k mile truck? LOL OK.

Chevys vs Dodge engines? Engines are air pumps, they all do the same thing the same way with no knowledge of the make they are in.

BTW, my car is N/A, not procharged so the principle is the same, just scaled back for stock vehicle and I never said the Mighty Mouse system was needed on these trucks, I said its what I will run. I prefer an overbuilt combination vs one that will work.

Fact is, you thought you needed to step in and correct someone with your "molecular separation and angular velocity" science. I deal with people like you all day every day whether its relative to high performance or in my day job of IT. Everyone of you guys has your "best practices" and formulas but have never put them to use in the real world where there's 1000's of variables and almost every time, you guys ideas don't work out in the real environment.

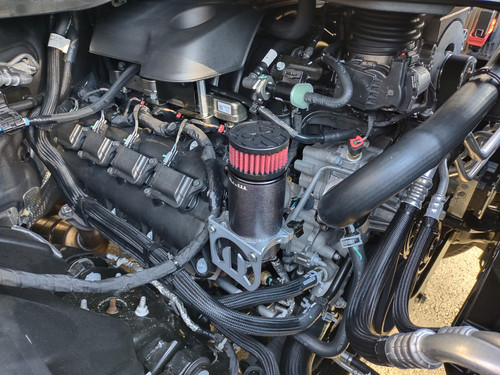

Ex, you claimed my PCV system would cause oil in my intake and that my rings where possibly bad, both proven wrong so you craw-fished in to some BS maintenance as to why my intake was clean. I built this car to beat the pi** out of and that's what I do, I didn't build it to have to work on every week and I don't.

I'm not in the least concerned about the performance of the catch can, I stated my preference, period and that not all were the same. Lastly, Hellcats don't come with a catch can soooooo.