Last week the night I returned from MT:

drilled into the bed side and added stabilizing mounts for the GFC.

Through our testing on other two GFCs we have/ had in our Boogielanding group, we found out that although GFC mounts keep the camper secure to the bed, they don't do a good job preventing the camper from shifting forward when the rear end bucks around while boogieing. With these brackets/ tabs, the forward motion/ momentum created while boogieing are stopped and the camper stays in place.

View attachment 170887

Today:

I left for MT with about 1k mile left before my 5k oil change interval, so I knew this batch of oil would go for about 6K miles instead. We don't do oil change, fluid change, or major repair work before big trip just in case something fails or leaks, unless the repair work is required to return the vehicle back to proper working order. So I figured, screw it, I'll do maintenance work after I come back.

View attachment 170888

Fumoto valve is such a game changer. This is actually the first time I use it on my truck. No more messy oil drains!

Initially I thought I could do the oil change without removing my RCI skid. After I lifted the truck up and looked at it I realized my fat hand and fingers would make it an impossible task, so I removed the skid. I simply unbolted the 3 bolts in the rear and loosen the front two bolts and the whole thing slides out. Skid plate came off and back on in 30 seconds.

So if you're on the fence about the skid and worry about oil change, just know that it's not that difficult to remove the skid plate and go ahead and order them. RCI is doing Black Friday Sale RIGHT NOW for up to 25% off skid plates.

View attachment 170889

I also used the OilUdder thing to change the filter. It took some practice to get it in (hehehe

) but once it's in it works wonders. (hahaha

)

First time ever with no mess oil change. I left the oiludder at the shop to make my life a lot more easier in the future.

While the truck was up in the air I also rotated the tires. It's been about 10k miles or so since these tires went on so... Since I have matching spare but spare has no TPMS and I'm planning to keep running AT3Ws for the next set, I only did 4 tires rotation instead of 5 like I usually do.

Then, owner of the shop next door saw me working alone and thought I was taking side jobs (which my friend/ boss is totally ok with) so we started chatting. Dude was impressed with the GFC when he was shaking on it.

View attachment 170891

Anyways, it was time for wiring inside the GFC. I started by disassembling the switch box I made for when I had the bed rack.

View attachment 170890

Made a plate for the fuse boxes and stuff. This is a temporary solution since I'm waiting on a few parts to come in and designing new plates and mount. That's why the bolts are way too long and I stacked washers and split washers lol (yes, my dumbass forgot to order bolts)

View attachment 170893

And the BlueSea System stuff are bolted in. Those will be exposed instead of inside a box since the GFC is technically a box that keeps water out, so no need for me to do another box.

Not pictured: cooking lights installed and hooked up, BD chase lights installed and cables extended.

I'm really not a big fan of these short sunlight days... it got dark at like 5PM and I had so much more to do! Guess I'll continue tomorrow.

Possible direction for future:

1. Since I have a MOLLE panel on order and I have no idea when that's coming in, the fuses may or may not be going to the MOLLE panel at the bulkhead. Pro: keeps everything clean and restore my bed rail for tiedown duty. Con: I have to redo all the wiring, which is not really a problem for me because that'd be just another day in the office.

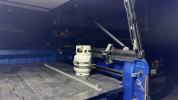

2. Swap out the current mount with a custom plate to hide all the wires and call it a day. Pro: keeps everything simple. Con: Render part of the bedrail useless, but that's not 100% a problem because the usable space of the bed rail on the other side is shortened due to propane mount.

We'll see when we get there I guess.

) but once it's in it works wonders. (hahaha

)