ZombieSlayer

Ram Guru

Well yea don't just use a 3 inch screw  However there must be enough of a void (especially along the bottom) to be able to use the same size screw that would mount the "proper" heat sink.

However there must be enough of a void (especially along the bottom) to be able to use the same size screw that would mount the "proper" heat sink.

Consider modifying the plastic vs cutting the heat sink tabs. It looks like you should be able to melt/cut a semi-circle for the bottom mount pretty easy. You might even be able to screw in the one tab that will be sticking out.

I was thinking about what you said about cutting a notch for one of the ears. With a mirror, I can’t see what is behind the spot I need to cut so I would probably have to split the case from the lens to check. Also, I think I’d have to silicone the cut area since the back of the tailights get a steady stream of water/ salt/ etc., when it’s wet on the road.Well yea don't just use a 3 inch screwHowever there must be enough of a void (especially along the bottom) to be able to use the same size screw that would mount the "proper" heat sink.

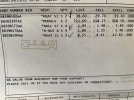

So it turned out to be a disaster. I’m just ordering a heat sink and extra sensor from ebay for $150. Shame that my parts guy can’t even find the left-hand heat sink since it only cost me $6.41 for the right hand one.Good point. And the backs of these housing s get a lot of rod splash. Min were filthy when I took them out to get a look at the 2 jumpers.

The screws that come with the sensors are like maybe 3/8” ish. But even at that length, I’d still be careful to make then dodge (hey-ohhhh!) the circuit boards in there. Hahha

Sent from my iPhone using Tapatalk

I’m just going off of the amount of time it took me to get 1 of the 2 heat sinks- I haven’t been able to try to order yet. (discovered that part# right before my last couple posts)Oh snap!!!! So how was it cutting that tho?

And that’s the same part number I found that had the ambiguous description. Lemme know if it IS actually the left one… in a month. That sucks that that’s the lead time.

Sent from my iPhone using Tapatalk

Oh, that was pretty easy with an oscillating tool and a couple drywall bits. The cuts were pretty straight, and I cleaned up any high spots with a dremel and a thin carbide bit on medium speed. When I was dremeling, I held a shop vac up to my cutting area to not send a bunch of tiny hot plastic pieces everywhere.Oh I was actually referring to the cutting of the backside of the light housing where the heat sinks attach. The part you tyvek’d up.

But yes the heat sinks seem like some soft aluminum.

Sent from my iPhone using Tapatalk

Jimmy, if you are still making the harnesses that go from the under seat to the Can system for BSM, can you PM me with a quote? I appreciate it.The canbus wires will always be missing from under the driver seat to the star can block on non equipped trucks.

Check your wiring and also check that you didn’t cut one of the circuit boards in the tailight.Started it up and now i got this on the dash.

Sent from my iPhone using Tapatalk

I haven’t tried yet, but am curious. I’ll let you know in 5 minutes thoughI guess now that I think about it, this light is junk anyway so I should actually try to fully open it and see if I can figure out what’s going on, anyone have any tips of separating the plastics on these??

Sent from my iPhone using Tapatalk

I think the tail light might have some kind of adhesive on it in addition to the screws- if the screws are even to assist in holding the cover on. (Which I’m unsure of)