Another informative article...

Other than knowing how to twist off the fuel cap, operate the self-serve pumps and complain about oil sheiks and prices, do you know how the energy that powers rubber tires, steel wheels, props and turbines gets to us?

"Getting Around" hopes to enlighten you.

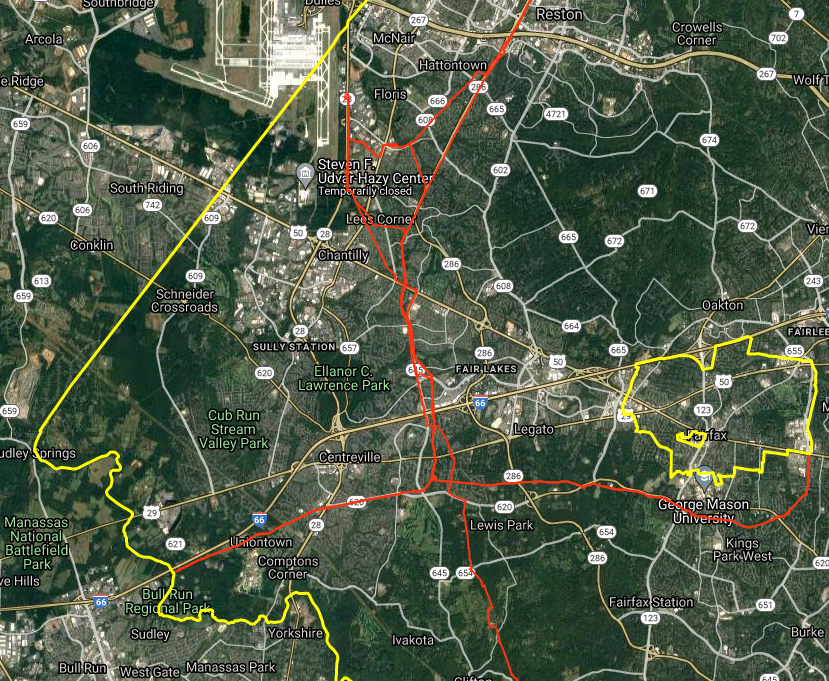

I know you know that Exxon, CoGo's, BP, Gulf, Sunoco, Texaco, A-Plus, 7-Eleven, Mobil, Citgo and every other brand of gasoline sold in the Pittsburgh region travels thousands of miles to get here.

But did you know all brands are basically generic as they flow from refineries through the same pipelines?

Did you know regular unleaded gasoline, premium grade gasoline, diesel fuel, jet fuel, kerosene, propane and other distilled petroleum products also share the same pipelines to Pittsburgh and every other place?

Did you know there's a nationwide network of 114,000 miles of the underground pipes that collects crude oil from oil fields still in production in the U.S. and transport it to refineries for processing?

Did you know there's a related nationwide network of 85,500 miles of pipes, up to 48 inches in diameter, that then distributes the petroleum products from the refineries to communities such as ours for use in manufacturing, home heating and commercial, public and personal vehicles?

And.......

If everything is one big batch coming out of the same pipe, what's the difference in gasoline brands?

"Once the basic product fulfills the requirements that any refinery can meet, the individual companies put in additives specific to their sales," said Michelle Joy, general counsel for the oil pipeline trade group. "The additives can do everything from boost engine performance to clean the engine with a special detergent."

Amoco is the only gas segregated from other brands, she said. "It's a clear gas, an exclusive environmental product not made by anyone else. When we're moving Amoco, we're moving it as a separate batch."

If everything comes out of the same pipe, back-to-back, how do they separate the dozens of products and grades of gasoline making long journeys from refineries to markets?

A briefing paper from the Association of Oil Pipe Lines and American Petroleum Institute explains:

"The physical principles of hydraulics keep batches of liquid from blending and contaminating one another except where they actually touch. The 'interfaces' from the different shipments are separated out when they arrive at destinations and are re-processed.

"Sometimes batches are separated by metal 'pigs' or plugs that keep batches from touching. Pigs are also used for cleaning interior surfaces of pipelines to help prevent corrosion. Specially developed 'smart pigs' containing instrumentation packages are used to double check pipeline integrity."