LOL thanks for the chuckle folks.

As for if it's safe or not. The rule of thumb is that you will get maximum grip with a thread engagement of 1.5x the diameter. So a 14 mm nut should screw on 21 mm to have the most grip. That is dependent upon some variables such as materials, thread type, etc. but it's a good start.

The stock lug nut is 1.51" deep, but it's only threaded about half of that depth.

The stock lug stud is roughly 1.58" long. Obviously the wheel takes up some of that length. Using my stock wheel I counted how many revolutions the nut makes from start of engagement to contact with the wheel. By turning 12.5 times it engages 18.75mm (or 0.738") on a M14 x 1.5 thread.

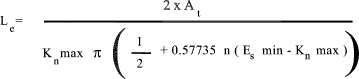

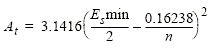

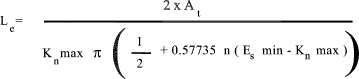

As you can see, the OEM nuts aren't using the maximum engagement, which isn't a big deal. I doubted they were at the minimum engagement either, so I did some math. Doing some calculations with a M14 x 1.5 thread (↓ reference formulas ↓) we can figure out the minimum engagement needed.

Having done that, the minimum thread engagement can be determined to be 0.4634" (or 11.08mm).

A 5 mm spacer will essentially lessen the stud length by 0.196" so you'll end up with 0.542" of thread engagement instead of 0.72. However, you'll note that is still a bit more than the minimum 0.463".

Summarized:

An M14 x 1.5 thread should engage 11.76 - 21 mm of length. Any less risks shear, any more is redundant.

Stock configuration engages 18.75 mm which is a tad over the middle.

A 5 mm spacer reduces engagement to 13.75 mm which is on the low side, but still more than the minimum thread engagement.

For my Imperial friends:

An M14 x 1.5 thread should engage 0.463" - 0.826" of length. Any less risks shear, any more is redundant.

Stock configuration engages 0.738" which is a tad over the middle.

A 5 mm (0.196") spacer reduces engagement to 0.542" which is on the low side, but still more than the minimum thread engagement.

At the end of the day, you could technically run a 7mm spacer and still be right on the cusp of spec, but I wouldn't do it. Having done the calculations, I'd be comfortable running a 5 mm spacer on my truck, but as previously mentioned, play at your own risk.