Mechaero19

Active Member

- Joined

- Feb 25, 2019

- Messages

- 49

- Reaction score

- 47

- Points

- 18

- Age

- 41

Here is an update to the new design I am working on. I have been taking a slow approach at this. More so an engineering approach. I have some solutions to the water drainage. Its an exciting project I made for myself and I am up for the challenge.

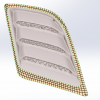

SO after some thought, in the previous posts, you can see I was trying to generate a mesh on the entire part. Problem with that, it is too complicated because of the diamond shapes, and the topology is very complex. SO....I asked myself, what DO I really need from the factory part, to design my own vent. And the answer to that...……..the perimeter of the part. I need this only, since the center portion will be redesigned, and it will hopefully guarantee a factory fit to the hood contours. So check out what I have come up with. The great part about this is if I get it 3D printed, I can manually hand sand the parts edges straight....or I can spend more time aligning the mesh. I think I will go with both, align the mesh more, and sand it. I will confirm the shape with a 1:1 print on paper just to see how things line up. I tried to get the sharp bend as close as possible.

So since the last post, ive learned a lot with power surfacing, with solidworks. I am going to take a crack at it with designing the vents from here. Its basically pulling points/surface/edges to conform to what you want.

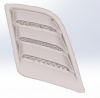

Picture 1: Fresh restart imported mesh file

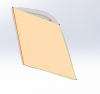

Picture 2: Manually drawin in mesh

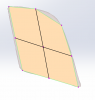

Picture 3: Took picture 2, and shows the subdivision with smooth edges

Picture 4: Took picture 3, and subdivided further

With multiple subdivisions, and aligning the mesh as best as possible, you get Picture 5.

In picture 5 you can see the amount or surface area i need from the edges. Anything more than that, the mesh gets distorted, but then again, the center is up for new design.

Enjoy my Emoji wheel:

SO after some thought, in the previous posts, you can see I was trying to generate a mesh on the entire part. Problem with that, it is too complicated because of the diamond shapes, and the topology is very complex. SO....I asked myself, what DO I really need from the factory part, to design my own vent. And the answer to that...……..the perimeter of the part. I need this only, since the center portion will be redesigned, and it will hopefully guarantee a factory fit to the hood contours. So check out what I have come up with. The great part about this is if I get it 3D printed, I can manually hand sand the parts edges straight....or I can spend more time aligning the mesh. I think I will go with both, align the mesh more, and sand it. I will confirm the shape with a 1:1 print on paper just to see how things line up. I tried to get the sharp bend as close as possible.

So since the last post, ive learned a lot with power surfacing, with solidworks. I am going to take a crack at it with designing the vents from here. Its basically pulling points/surface/edges to conform to what you want.

Picture 1: Fresh restart imported mesh file

Picture 2: Manually drawin in mesh

Picture 3: Took picture 2, and shows the subdivision with smooth edges

Picture 4: Took picture 3, and subdivided further

With multiple subdivisions, and aligning the mesh as best as possible, you get Picture 5.

In picture 5 you can see the amount or surface area i need from the edges. Anything more than that, the mesh gets distorted, but then again, the center is up for new design.

Enjoy my Emoji wheel: