John Jensen

Well-Known Member

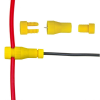

I tapped into the trailer wiring harness. My tapping method is to expose the harness wire, wrap the connecting wire, solder, and triple+ tape. Been doing it that way for over 70 years for 22-10 gauge wiring, and never had a problem. And, if any tech does a crimp drvice splice, I correct it with a soldered splice