E.Hands

Well-Known Member

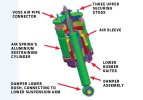

Only other feedback is, when you get it done, you will be happy that you did it.@E. Hands, any more feedback on the swap? Any modifications necessary like it seems was required (shims) on the 4th gens? I'm looking at swapping 5100's on my front shocks since I've got 5100s on my rears already. Part number I'm looking at is 24-300872. Replacing the rears really helped the ride at 106k miles on my Limited. Now I'm realizing my fronts need swapped pretty bad. Hoping the extra grooves on the fronts will keep me away from needing to purchase the special ones with the groove machined in that special spot.

And pleased with the money that you saved doing it!