My20231500

New Member

- Joined

- Oct 19, 2023

- Messages

- 4

- Reaction score

- 1

- Points

- 3

- Age

- 47

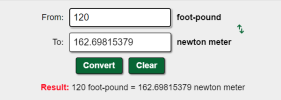

Hi I’m a new ram 1500 owner. I bought the bedstep to put on my truck. I was able to get it on but I could not torque it to the spec of 124 ft lb. I took it to the dealership to have them tighten the three screws but they said they wouldn’t go above 60 since that seemed too high for the screws. It looks like some others were able to install to the specs. Have you had any issues or is it ok to keep it slightly looser? I was surprised how easy it was to unscrew but how hard to torque it back on. Thanks