So my first "need" was to use the bed rails that came on the truck. I mean why not, that's what they are there for. Plus in my opinion RAM has done a **** poor job of providing ample accessories and fun things that can use these bed rails. I mean come on, the only thing I've found from RAM were the uber expensive cross rails that I think are discontinued now? WTF Ram. Anyway so where I work has a GREAT 'creativity' center that fosters ideas and innovation. This in turn gives me almost unlimited access to seriously cool power tools, 3D printers, laser cutters, CNC routers etc. Yea, be jelly. Alright so my first step was I wanted to find an alternative to having to use t-slot nuts for connecting into the rails. Because they lock in place when tightened and I wanted something that would allow me to slide out the two panels of my forthcoming tonneau cover. Boom challenge accepted.

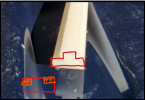

So we had a buttload of HDPE scrap sheets (same stuff that cutting boards are made from) lying aroung. And I'm like...hmm what if I use that as a long strip to slide into the channel... Hello Table saw, oh hi there digital calipers lets be friends. Done.

The scraps, fun begins here:

View attachment 76050

Super technical measurement gathering format system:

View attachment 76051

the strips...not to be confused with ol' fashioned whippin switches from the yard your momma told you to get for an *** whoopin

View attachment 76052