Full credit goes to HDRAMS member Tom2531. Reprinted below.

hdrams.com

hdrams.com

This post is about the brake controller on the 2021 HD Ram. First, my story. Second some reverse engineering and description of the warnings on the dash. Finally, some technical details. I would assume this information would apply to other years in the same generation of truck, but outside of that, I don’t know.

I was greeted with Check Trailer Brake Wiring/Trailer Brake Disconnected on our first trip out with our 2021 2500 and travel trailer combo. The same trailer on our 2018 1500 had no issues earlier in the year. At first it happened after a few hours. Sometimes it would just say Check Trailer Brake Wiring, and other times it would ding and say Trailer Brake Disconnected. I read this related post: Trailer Brake Disconnected. I found I had the “old” style 7 pin connector, and I needed to extend mine anyway – so I ordered a Hopkins HM20048 and put that on. The first time I plugged it in, I had no brakes and no left turn signal on the trailer. I bent the pins a little and got them working. Unfortunately, after a short while on the next trip, the error returned.

What bothered me is the error wasn’t real helpful. I wasn’t sure if I had a short, break, or something intermittent. Nor did I know if the problem was in the truck or trailer. I went about troubleshooting and here is what I learned.

I started testing with load resistors (6 Ohm 50W) that simulated trailer brakes. With 2-6 ohms, the truck would detect a trailer connected. But when I got down to 1.5 ohms, the CTBW/TBD cycle of errors would begin. So would a dead short.

If a short or high current on the brakes is detected, after 1 second you will see CTBW. If the problem goes away during that time, the message will go away. If the condition exists for another 5 seconds, it goes to TBD. If the problem goes away at this point, this will clear also. But if the condition persists, it will cycle between CTBW and TBD every 5 seconds.

While a short or high current scenario is detected, THE BRAKE CONTROLLER WILL NOT OUTPUT A BRAKE SIGNAL. If the short condition is resolved while already braking, the brakes will come on (I experienced this once – when stopping, there were no trailer brakes to start so I got into the truck brake, then the trailer brakes kicked in and scared the crap out of me). If you are braking when a short is detected, it will continue to brake assuming the short isn't bad enough. But as soon as the brakes are released the short will be detected, and the output disabled.

In contrast, an open connection to the trailer brakes will delay for one second, then you will see TBD. The red no trailer icon will persist as long as the brake wiring shows an open circuit.

Etrailer has some good articles on expected current (amps) and resistance (ohms) for different trailer configurations. That’s a good place to start to troubleshoot the trailer wiring. I won’t rehash that here.

If the trailer had checked out, I was planning to connect a load resistor (6 ohms 50W will do it – just be aware it will get hot when braking) across the ground/brake pins of the connector on the truck and drive around with my “virtual” trailer. If there had been a short or break in the truck wiring, my thought was that it would show up and not have all of the complications of a real trailer to troubleshoot. It would have made troubleshooting with the dealer easier.

The brake controller uses PWM (pulse width modulation). With no trailer connected, it sends out a 12V DC 1ms pulse 3 times a second. When the trailer is connected this voltage will drop a little but this “sensing” pulse continues to check if the trailer is connected. I can actually hear this in my brakes – there is a slight ticking noise coming from the trailer brakes 3 times a second. When you brake, a 250Hz 12V DC PWM signal comes out, with the duty cycle proportional to your braking, as well as gain and trailer settings. The PWM sensing pulse is there all the time even if there is not a trailer connected. Even with an open circuit, the brake controller will still output a full signal when braking. But if it gets shorted or the braking current (amps) is too high, it will shut off. It still senses 3 times a second when shorted and if the short is resolved, it will begin to output again. I would assume the one second delay earlier is three tries before it gets disabled.

Edit: Be sure to see Part 2 below: Factory Trailer Brake Controller Troubleshooting and Technical Info (from HDRAMS)

Brake Controller Troubleshooting/Technical Info

This post is about the brake controller on the 2021 HD Ram. First, my story. Second some reverse engineering and description of the warnings on the dash. Finally, some technical details. I would assume this information would apply to other years in the same generation of truck, but outside of...

This post is about the brake controller on the 2021 HD Ram. First, my story. Second some reverse engineering and description of the warnings on the dash. Finally, some technical details. I would assume this information would apply to other years in the same generation of truck, but outside of that, I don’t know.

I was greeted with Check Trailer Brake Wiring/Trailer Brake Disconnected on our first trip out with our 2021 2500 and travel trailer combo. The same trailer on our 2018 1500 had no issues earlier in the year. At first it happened after a few hours. Sometimes it would just say Check Trailer Brake Wiring, and other times it would ding and say Trailer Brake Disconnected. I read this related post: Trailer Brake Disconnected. I found I had the “old” style 7 pin connector, and I needed to extend mine anyway – so I ordered a Hopkins HM20048 and put that on. The first time I plugged it in, I had no brakes and no left turn signal on the trailer. I bent the pins a little and got them working. Unfortunately, after a short while on the next trip, the error returned.

What bothered me is the error wasn’t real helpful. I wasn’t sure if I had a short, break, or something intermittent. Nor did I know if the problem was in the truck or trailer. I went about troubleshooting and here is what I learned.

Brake Controller Operation

In the rest of this post, I will refer to the two warning messages and accompanying indicators/audibles as CTBW and TBD.- CTBW: Check Trailer Brake Wiring – white text, no audible ding, the trailer disconnected icon is not lit

- TBD: Trailer Brake Disconnected – white text with red background, a single audible ding, trailer disconnected icon is lit (red trailer with slash through it in the upper right portion of the dash)

I started testing with load resistors (6 Ohm 50W) that simulated trailer brakes. With 2-6 ohms, the truck would detect a trailer connected. But when I got down to 1.5 ohms, the CTBW/TBD cycle of errors would begin. So would a dead short.

If a short or high current on the brakes is detected, after 1 second you will see CTBW. If the problem goes away during that time, the message will go away. If the condition exists for another 5 seconds, it goes to TBD. If the problem goes away at this point, this will clear also. But if the condition persists, it will cycle between CTBW and TBD every 5 seconds.

While a short or high current scenario is detected, THE BRAKE CONTROLLER WILL NOT OUTPUT A BRAKE SIGNAL. If the short condition is resolved while already braking, the brakes will come on (I experienced this once – when stopping, there were no trailer brakes to start so I got into the truck brake, then the trailer brakes kicked in and scared the crap out of me). If you are braking when a short is detected, it will continue to brake assuming the short isn't bad enough. But as soon as the brakes are released the short will be detected, and the output disabled.

In contrast, an open connection to the trailer brakes will delay for one second, then you will see TBD. The red no trailer icon will persist as long as the brake wiring shows an open circuit.

Trailer Troubleshooting

From there I connected the truck to the trailer again, and (luckily) it cycled CTBW/TBD. I cut the brake wiring and only connected the brakes on the front axle of the trailer, and the error went away. The back axle brakes by themselves caused the error. When splitting the back axle in to left/right, the short disappeared entirely, so I suspect the issue is in one of the wires. I’ll be re-wiring the trailer brakes soon to remedy the issue.Etrailer has some good articles on expected current (amps) and resistance (ohms) for different trailer configurations. That’s a good place to start to troubleshoot the trailer wiring. I won’t rehash that here.

Truck Troubleshooting

(I didn’t go this far, but this was my plan)If the trailer had checked out, I was planning to connect a load resistor (6 ohms 50W will do it – just be aware it will get hot when braking) across the ground/brake pins of the connector on the truck and drive around with my “virtual” trailer. If there had been a short or break in the truck wiring, my thought was that it would show up and not have all of the complications of a real trailer to troubleshoot. It would have made troubleshooting with the dealer easier.

Technical Details

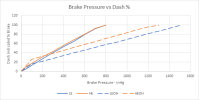

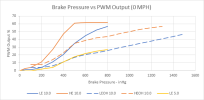

I put a oscilloscope on the trailer wiring so see what it was really doing.The brake controller uses PWM (pulse width modulation). With no trailer connected, it sends out a 12V DC 1ms pulse 3 times a second. When the trailer is connected this voltage will drop a little but this “sensing” pulse continues to check if the trailer is connected. I can actually hear this in my brakes – there is a slight ticking noise coming from the trailer brakes 3 times a second. When you brake, a 250Hz 12V DC PWM signal comes out, with the duty cycle proportional to your braking, as well as gain and trailer settings. The PWM sensing pulse is there all the time even if there is not a trailer connected. Even with an open circuit, the brake controller will still output a full signal when braking. But if it gets shorted or the braking current (amps) is too high, it will shut off. It still senses 3 times a second when shorted and if the short is resolved, it will begin to output again. I would assume the one second delay earlier is three tries before it gets disabled.

Edit: Be sure to see Part 2 below: Factory Trailer Brake Controller Troubleshooting and Technical Info (from HDRAMS)